On December 20, 2024, American Battery Factory announced a partnership with China’s KAN Battery to officially launch a pilot production project for lithium iron phosphate batteries. Through this pilot project, ABF aims to integrate manufacturing technologies with business analytics to refine production processes, preparing for the construction of its gigafactory in Tucson, Arizona. As part of this collaboration, ABF will establish its subsidiary, ABF China, which will utilize 1GWh production facility for high-capacity prismatic batteries.

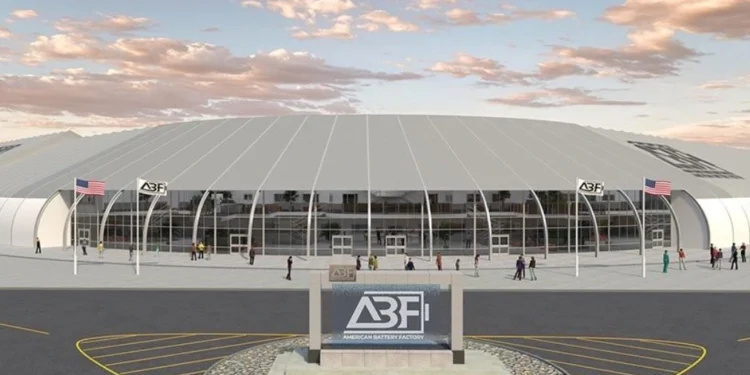

The ABF China facility, covering 750,000 square feet, will manufacture high-capacity prismatic batteries with outputs ranging from 105Ah to 300Ah and optimize battery chemistry to meet UL certification standards. The Tucson gigafactory project will include the company’s headquarters, an R&D center, and initial 2GWh factory modules. With a total investment estimated at $1.2 billion, the 2-million-square-foot facility is expected to create 1,000 local jobs and complete its first phase by the second half of 2026.

ABF President John Kem said, “Working with KAN Battery gives us an opportunity to bring expertise back to the United States and train U.S. workers with the best manufacturing and chemistry innovation available to date. This will help us leap forward, bringing our line of lithium iron phosphate prismatic cells to our U.S. gigafactory for full-scale production”.

ABF is committed to providing high-safety, environmentally friendly battery designs to meet energy storage demands for utilities, data centers, telecommunications, agricultural equipment, and defense markets. Driven by the pilot project, the U.S. battery energy storage market is poised for significant growth. According to the International Energy Agency, China is home to almost 100% of the LFP production capacity. Collaborating with global leading battery manufacturers will help ABF reduce the technology gap in battery production and foster the development of a domestic supply chain through global cooperation.