According to Newswise, in a world-first technological advancement, researchers at the Korea Institute of Machinery and Materials (KIMM) have introduced a roll-to-roll (R2R) compatible flash process to lithium-ion battery electrode manufacturing. This innovation significantly reduces performance degradation in thick electrodes, paving the way for higher energy density, lower production costs, and improved battery efficiency.

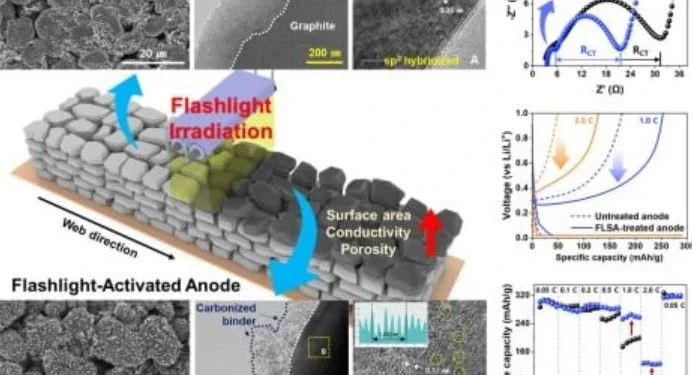

By implementing ultra-fast photothermal reactions, the flash process enhances lithium-ion transport, increases porosity, and optimizes electrode-electrolyte interaction, addressing long-standing challenges in thick electrode production. This advancement marks a significant step toward making lithium-ion batteries more compact, cost-effective, and sustainable.

How the Roll-to-Roll Flash Process Enhances Battery Performance

The newly developed electrode activation technology utilizes flashlight irradiation for less than one millisecond, triggering instantaneous chemical and structural modifications that optimize thick electrode functionality. Key benefits of this process include:

- Increased Lithium-Ion and Electron Transport: Flash-induced binder carbonization and active material expansion reduce internal resistance.

- Improved Electrolyte Penetration: Enhanced porosity and interlayer expansion facilitate better ion diffusion, boosting overall electrochemical performance.

- Minimized Material Degradation: The photothermal reaction prevents prolonged exposure to high temperatures, preserving mechanical durability and preventing oxidation-related damage.

By integrating this technology into roll-to-roll manufacturing, the process is scalable for mass production, making it compatible with existing lithium-ion battery production lines.

Addressing Challenges in Thick Electrode Battery Manufacturing

While thick electrodes offer advantages such as higher energy density, fewer battery pack layers, and simplified structures, they also present key challenges:

- Higher resistance to lithium-ion transport reduces rate capability.

- Limited electrolyte penetration affects efficiency.

- Increased manufacturing complexity raises production costs.

The flash process technology directly addresses these issues by enhancing electrode conductivity, improving electrolyte diffusion, and ensuring long-term performance stability.

Future Applications and Industry Collaboration

KIMM is now collaborating with leading lithium-ion battery equipment manufacturers to scale up the roll-to-roll flash process for mass production. The research team is also exploring its application in electrode drying stages, demonstrating a significant reduction in energy consumption and processing time. The technology’s compatibility with multiple electrode materials, including nickel-cobalt-manganese (NCM) cathodes, makes it highly adaptable for future next-generation battery innovations.

Recognition and Industry Support

This groundbreaking research has been recognized globally, securing a cover article in the February 2025 issue of Small Methods (Impact Factor: 10.7), a leading materials and chemistry journal.

The project is backed by the Korean Ministry of Science and ICT and the Ministry of Trade, Industry, and Energy, further validating its potential impact on the lithium-ion battery market.

Key Industry Insights and Market Implications

With the global push for sustainable energy storage solutions, the roll-to-roll flash process is poised to redefine battery manufacturing by:

- Lowering battery production costs through efficient material utilization.

- Enhancing battery energy density, crucial for EV and renewable energy storage applications.

- Reducing the carbon footprint of lithium-ion battery manufacturing.

Conclusion: A Game-Changer for the Lithium-Ion Battery Industry

The roll-to-roll flash process technology represents a major leap in lithium-ion battery manufacturing, offering higher efficiency, lower costs, and enhanced sustainability. With global industry players backing its commercialization, this breakthrough is set to reshape the future of energy storage and electric mobility. As battery technology continues to evolve, scalable and cost-effective innovations like this will be key drivers in making next-generation lithium-ion batteries more accessible and efficient for a greener, more sustainable future.

Want to stay updated on the battery industry? Check out the latest news on BatteriesDaily!