According to Technology Networks, researchers at the University of Leicester have pioneered a novel, eco-friendly method to extract valuable metals from lithium-ion battery waste using a mix of water and vegetable oil. This breakthrough technique, developed under the Faraday Institution’s ReLiB project, provides a cost-effective and environmentally sustainable alternative to conventional battery recycling processes.

Key Innovations in Battery Recycling

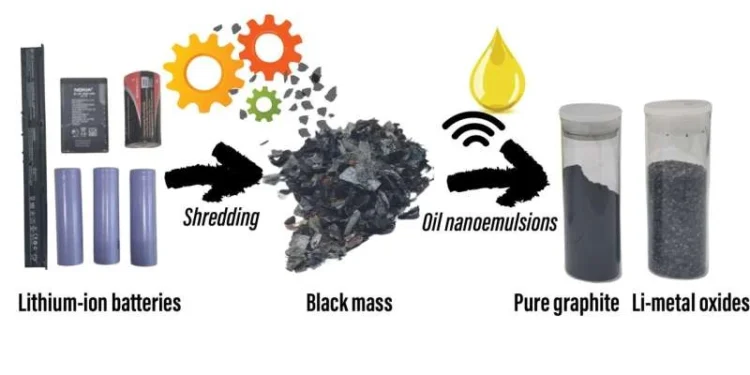

The patent-pending process allows the purification of lithium-ion battery black mass—a waste mixture containing anode, cathode, graphite, lithium, nickel, and cobalt metal oxides—within minutes at room temperature. Unlike traditional pyro- and hydrometallurgical methods, which require high temperatures and harsh acids, this technique offers:

- Lower Carbon Footprint: Eliminates the need for high-temperature furnace treatments, reducing CO₂ emissions.

- Minimal Chemical Waste: Avoids the use of corrosive acids in metal extraction.

- Short-Loop Recycling: Preserves the battery-grade crystalline structure, allowing direct reuse in new battery cells without complex reprocessing.

“This quick, simple and inexpensive method could revolutionise how batteries are recycled at scale. We now hope to work with a variety of stakeholders to scale up this technology and create a circular economy for lithium-ion batteries.” – Dr. Jake Yang, University of Leicester

How the Process Works

The oil-water nano-emulsion technique leverages ultrasound to create stable nano-droplets of oil, which selectively bind to hydrophobic graphite particles in battery waste. This process allows:

- Graphite Separation: Oil-graphite conglomerates float on water, enabling easy extraction.

- Purification of Lithium Metal Oxides: The remaining hydrophilic lithium, nickel, and cobalt oxides can be directly reused in battery production.

This method provides a more sustainable pathway for recycling EV batteries, reducing costs and environmental impact while ensuring the long-term viability of battery-grade material supply.

Addressing the Global Battery Waste Challenge

The rapid adoption of electric vehicles and consumer electronics has led to an exponential increase in battery waste. Currently, over 40 million EVs are in use worldwide, and 10 billion mobile devices rely on lithium-ion batteries. However, a lack of effective recycling regulations has led to inefficient battery waste management.

The University of Leicester, in partnership with the University of Birmingham, is now working under an Innovate UK-funded project, ReBlend, to develop a pilot-scale processing line capable of handling tens of kilograms of black mass per hour. This project aims to demonstrate that short-loop battery recycling can be economically viable for large-scale industry adoption.

“The ReLiB project is one of the Faraday Institution’s flagship projects developing innovative technology to capture value and retain scarce resources in the circular economy of battery manufacture and recycling. This work offers a promising route for short-loop recycling of lithium-ion batteries at scale.” – Professor Martin Freer, CEO, Faraday Institution

Future Outlook: A Circular Economy for Lithium-Ion Batteries

As EV adoption accelerates, the need for efficient, scalable, and eco-friendly battery recycling will become increasingly critical. By developing low-cost, sustainable solutions, the University of Leicester’s research presents an opportunity to reshape the battery supply chain, ensuring that valuable materials are continuously recovered and reused. With ongoing R&D investment and industry collaboration, this innovation is poised to transform lithium-ion battery recycling, supporting the global transition to a clean energy economy.

Reference: Lei C, Ryder KS, Abbott AP, Yang JM. Using ultrasonic oil–water nano-emulsions to purify lithium-ion battery black mass. RSC Sustain. 2025:10.1039.D4SU00771A. doi: 10.1039/D4SU00771A

Want to stay updated on the battery industry? Check out the latest news on BatteriesDaily!